Hello, Welcome to VIBRA Vibration Technology (Shanghai) Co., Ltd.

Information Details

Heard that PLA crystallization difficult? Come in, VIBRA tell you the answer!

2024-04-22

Keywords: Conveyor

Plastic brings convenience to human life, but it is difficult to degrade and cause pollution. Nowadays, with the growing demand for "green" and sustainable development in the whole industry, biodegradable materials are one of the more mainstream solutions to reduce plastic pollution. Among them, PLA, as a completely degradable material of bio-based raw materials, plays an important role.

Polylactic acid (PLA) is a new type of biodegradable material, which has attracted much attention due to its renewable characteristics, biodegradability, biocompatibility, high permeability, safety, non-toxic and other advantages. It can be widely used in food packaging, fast food lunch boxes, non-woven fabrics, industrial and civil fabrics, agricultural fabrics, 3D printing and other fields.

Compared with uncrystallized PLA, PLA crystallization has the advantages of increasing polymer molecular weight, improving material mechanical degree, processing performance, chemical performance, and preventing material adhesion. However, the slow crystallization rate and low crystallinity of PLA lead to its poor heat resistance, low mechanical strength and long molding cycle, which seriously restrict the application and development of PLA in green packaging automotive interior, engineering plastics, medical and health and other fields.

Comparison of PLA Crystallization Process

01 Infrared Heating

Infrared heating crystallization mainly provides heat through infrared light source, which belongs to continuous feeding, and the output can reach 2.5 tons/hour. However, the problem of material adhesion cannot be solved in the process of rotary motion, the friction between materials is relatively large, material particles are easily damaged, material wire drawing occurs, etc., and the energy consumption is high and the cost is relatively high.

02 Stirring

Stirring crystallization is mainly used in the laboratory, which belongs to batch feeding, and there are also problems such as large friction between materials, low output and high operating costs.

03 Vibration

Vibration crystallization is an effective treatment method at present, which belongs to continuous feeding. Compared with infrared crystallization, the output is as high as 8.5 tons per hour, and the friction between materials is relatively small. It can solve the problem of PLA adhesion in the crystallization process, and almost no additional input energy is required, and the operating cost is lower.

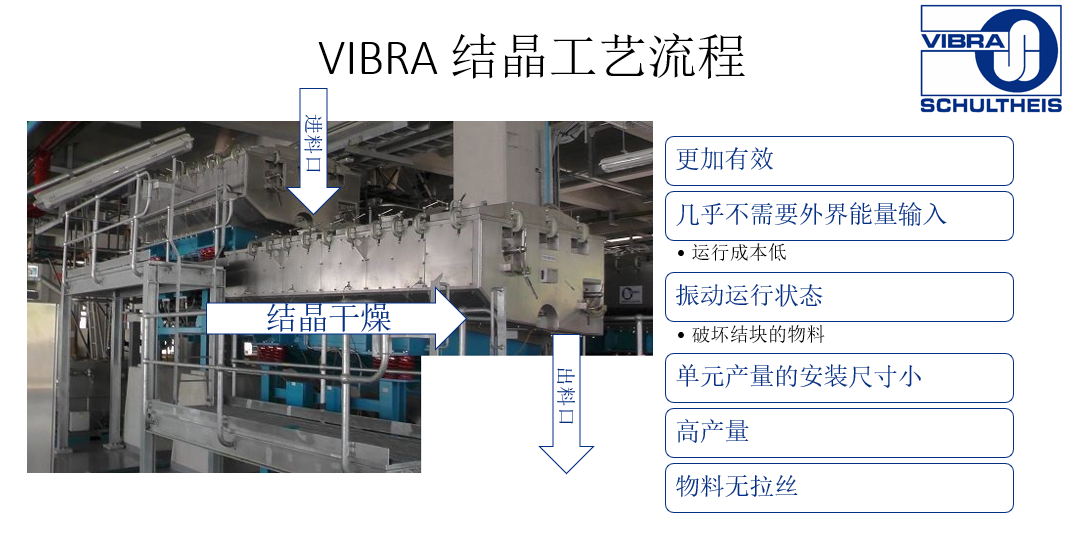

VIBRA Crystallization Process

As a global chemical company with a history of more than 75 years, VIBRA focuses on the manufacture of vibration equipment and the development of vibration technology.

Through continuous innovation and efforts, VIBRA has developed a series of crystallization, drying, crystallization, cooling, screening and conveying systems for PET, PLA and other plastic bodies. The system has invention patents in China, Europe and the United States. Compared with the traditional drying and crystallization system, the system can save energy consumption and expand production capacity.

Advantages of the VIBRA Crystallization Process:

Energy saving, low operating costs

Large single-line capacity, and is still increasing capacity

Modular design for easy maintenance

From professional design and planning, equipment manufacturing, installation and commissioning and after-sales maintenance, we can provide you with a series of services. At the same time, VIBRA has always been a practitioner of sustainable development. We are pointing our innovation direction to green, environmental protection, resources and energy, so as to achieve the goal of sustainable development.

To protect the green is to protect ourselves!

For more information, please contact us.

Related News

>

>