Hello, Welcome to VIBRA Vibration Technology (Shanghai) Co., Ltd.

Information Details

To reduce deviation and improve quality, it is necessary to give plastic particles a "big set" of VIBRA"

2024-04-22

Keywords: Conveyor

A question asked, "Why can't we stop making plastic products?"

One of the high praise replied: "because plastic is too widely used."

In addition to being used as disposable products, plastics are indispensable for the manufacture of automobiles, airplanes, and rockets.

With the increasing use of plastics, people's requirements for its production process and finished product quality control are becoming more and more stringent.

How to effectively solve the problem of plastic particles of different sizes?

What is the temperature and humidity control of plastic particles?......

Are these problems that will eventually affect the quality of plastic particles and their products a headache for you?

Let's take a look at the solutions of VIBRA, the global vibration technology expert

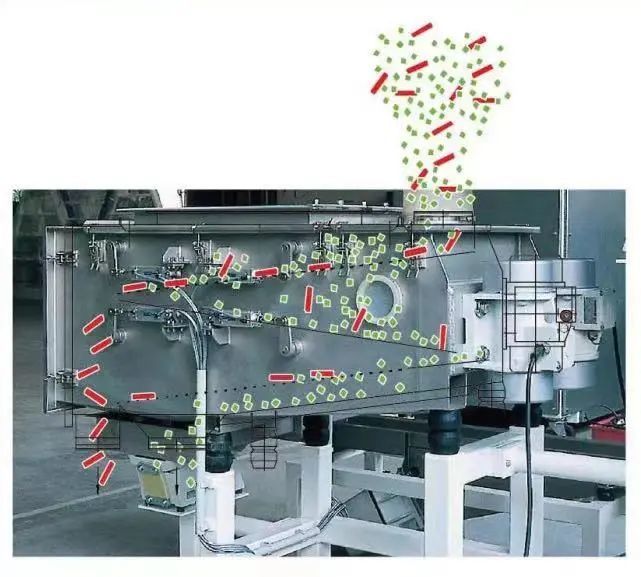

VIBRA SRK Removing Lengths from Granules, to stay pure "top"

The working principle of vibrating screen is the process of screening and grading materials by using the high frequency vibration of the screen body.

During the production process, it is inevitable that some long abnormal particles will be produced, and the long particles will not become "particles that leak through the mesh" if they lie flat and slide through the mesh ".

01"Flat" long particles, more uniform feed

In this regard, the SRK Removing Lengths from Granules adopts a direct vibrating screen body to avoid acceleration of long particles on the vertical screening surface as much as possible, so as to prevent them from bouncing on the screen surface and sliding down through the screen holes.

The steel plate in the feeding area can ensure more uniform feeding and at the same time level the long particles. In addition, the vibration motor can be adjusted in the specified angle range to optimize the feeding speed.

02 Single and double-layer screen to meet different needs

The screening efficiency depends on the diameter of the screen openings and the ratio of material particles.

In addition to the above operations, SRK Removing Lengths from Granules can also be used in the form of double sieve plates to screen fine particles.

03 Different structure design, save space on site

For users who have multiple screening needs, they can choose a laminated structure or a "zigzag" structure according to the site conditions to save available space.

04 Well designed for easy cleaning

There are no fixtures for supporting or screening components in the screen frame; and the punching plate is made of a single piece of steel plate, and there are no gaps or sharp corners that affect cleaning.

Vibrating Spiral Conveyors,Material handling and conveying "two hands"

The working principle of vibrating screen is the process of screening and grading materials by using the high frequency vibration of the screen body.

During the production process, it is inevitable that some long abnormal particles will be produced, and the long particles will not become "particles that leak through the mesh" if they lie flat and slide through the mesh ".

The Vibrating Spiral Conveyors is a professional vibration lifting equipment used for granular material transportation (or cooling, drying, heating, humidification), which effectively combines process processing and material transportation in a simple way.

Vibrating Spiral Conveyors can meet the needs of long-distance transportation. Due to the upward movement of materials in the form of micro-throwing on the inclined conveying surface, the larger contact surface between the conveying surface and the conveyed materials, which not only saves the site area, but also realizes the high efficiency of heat transfer.

It is more and more widely used in the field of mechanical conveying and heat treatment.

In addition to the plastics industry, VIBRA vibration technology has also been widely recognized in the food and pharmaceutical industry.

At the same time, we are developing new technologies and expanding new applications to bring vibration delivery technology solutions to more users.

About VIBRA

The VIBRA vibration technology from Germany was established in 1948 and has a history of nearly 75 years. Over the years, we have been focusing on the production and manufacture of vibration equipment and the development of vibration technology. We produce a series of high quality vibration series equipment: VIBRAting Conveyors, VIBRAting Screening Machines, VIBRAting Spiral Cooling/Heating Conveyors, Fluid-bed Dryer/Coolers, VIBRAting Motors, VIBRAting Magnetic Separators, VIBRAting Discharge, VIBRAting Sprinklers and so on, in the chemical industry, plastics, food, medicine and other fields have a very wide range of applications.

Related News

>

>