Hello, Welcome to VIBRA Vibration Technology (Shanghai) Co., Ltd.

Information Details

What do you need to pay attention to to completing the drying and screening process?

2024-04-22

Keywords: Conveyor

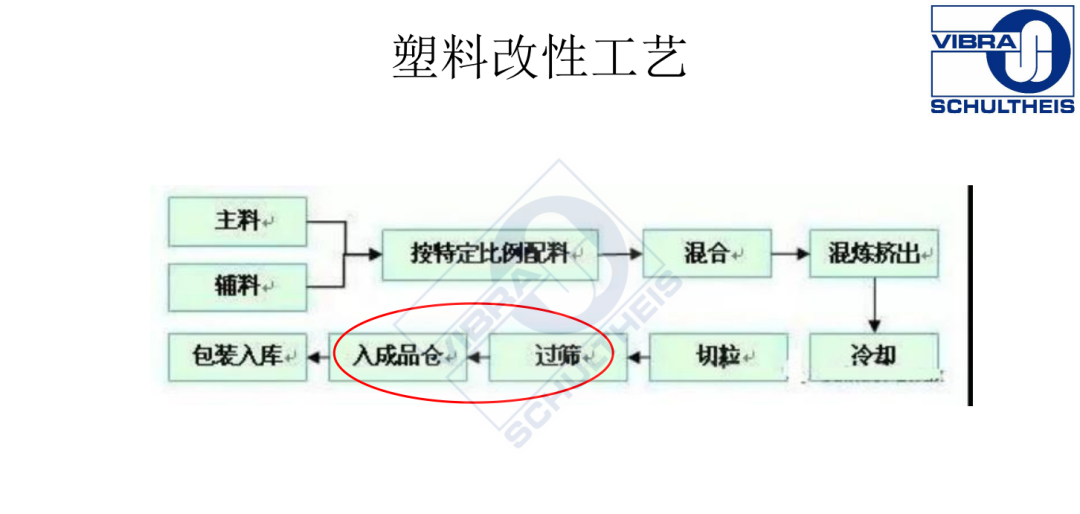

Drying and sieving is one of the seven major production processes in blending production, which plays an important and non-negligible role in blending production.

In the context of the current industrial upgrading, how to carry out high-quality vibration screening and drying of modified products is a necessary question for modified factories to improve the level of automation.

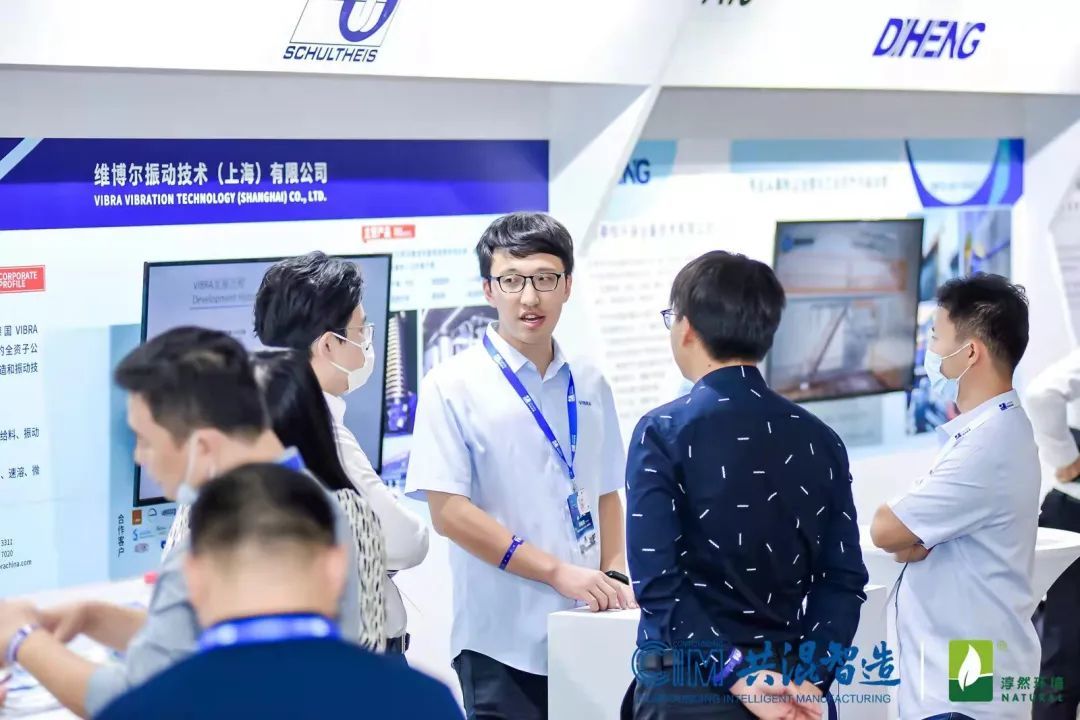

From September 16 to 17, the 2021CIM blending industry conference was held in Suzhou. More than 700 industry insiders and experts from the fields of blending modification, masterbatch, additives and degradation modification were invited to attend the conference, which focused on the topics of blending factory production process and management, industry automation intelligence, polymer material technology research and development, etc.

As a solution provider for the plastics industry and a supplier of advanced vibration technologies and processes, VIBRA is here with friends from the blending industry.

During the exhibition, our technicians introduced the core products and technical processes of VIBRA to the guests on the spot, and were invited to give a speech at the "Blending Modification Process Forum", one of the four parallel forums. The guests shared the solutions for effective drying and screening, improving production efficiency and product quality in the production granulation process.

In view of the practical difficulties encountered in the material handling process of the blending plant, Johnny.Liu, technical manager of vibor process, shared the theme of "material handling scheme of vibrating spiral hoist in blending plant" in the blending intelligent manufacturing-blending modification process venue, and proposed the solution given by vibor to this problem.

The "Application of Vibor Vibration Equipment in Modified Plastics Industry" program shared by Manager Johnny.Liu received extensive attention from the audience. Many participants expressed their interest in VIBRA vibration technology after the report and hoped to have continuous communication with the drying and screening program.

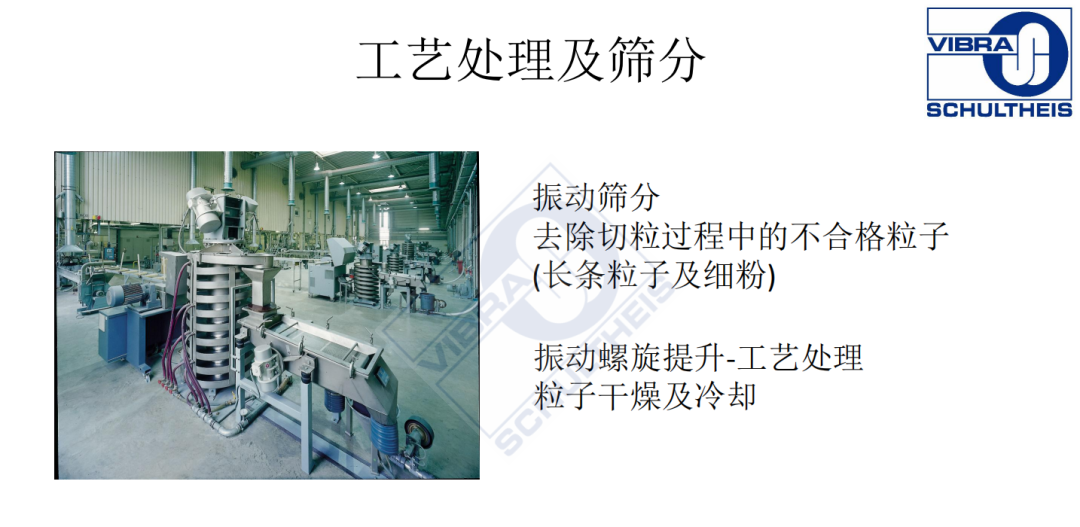

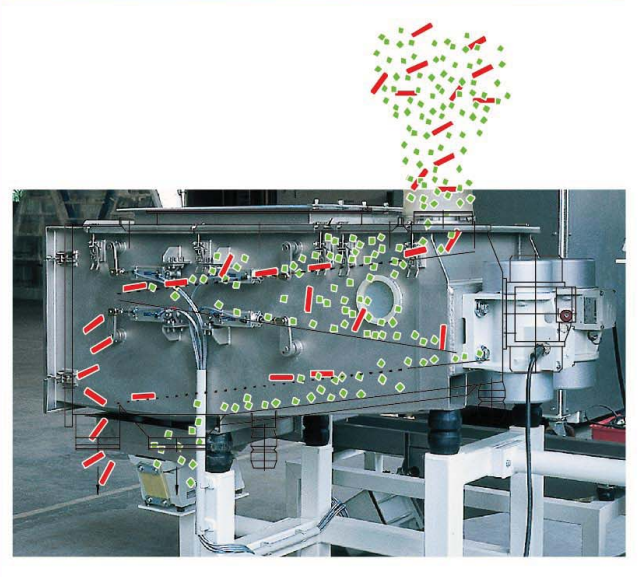

SRK Removing Lengths from Granules

VIBRA provides vibration screening equipment, can remove the unqualified particles in the process of pelletizing, to ensure the stability of product quality;

Through the special structure, the long particles are not easy to fall on the plane, the operation is simple, and the screening effect can be obtained.

Vibrating Spiral Conveyors

The vibrating spiral Conveyors can process both particles and powders, and has the advantages of small footprint, high lifting height, and low height of the feed inlet from the ground;

In addition, the vibrating spiral Conveyors can also reduce the energy consumption of the factory, and with the help of maintenance-free motors and easy-to-clean equipment, the operation and maintenance costs are greatly reduced;

Through the professional process of Vibor, the equipment can enhance the heat exchange of materials under various working conditions.

In the face of the new situation and new hot spots in the plastics industry, the Vibor team will join hands with blending enterprises to move towards a new ladder of industrial upgrading and continue to provide customers with convenient and advanced technology and equipment.

About VIBRA

The VIBRA vibration technology from Germany was established in 1948 and has a history of nearly 75 years. Over the years, we have been focusing on the production and manufacture of vibration equipment and the development of vibration technology. We produce a series of high quality vibration series equipment: VIBRAting Conveyors, VIBRAting Screening MachinesVIBRAting Spiral Cooling/Heating Conveyors, Fluid-bed Dryer/Coolers, VIBRAting Motors, VIBRAting Magnetic Separators, VIBRAting Discharge, VIBRAting Sprinklers and so on. in the chemical industry, plastics, food, medicine and other fields have a very wide range of applications.

Related News

>

>